The manufacturing sector is rapidly embracing the benefits of emerging technology. Operations large and small are maximizing shop floor efficiency by using autonomous mobile robots (AMR) to perform certain tasks, such as delivering components, assemblies, or products from one workstation to the next.

AMR industrial utility carts free up time and workers — both of which can then be allocated to higher-level duties. It’s an attractive proposition for manufacturers, and likely the basis for purchase decisions.

It can also be a source of confusion. OEMs in the AMR market are sometimes presented with automated guided vehicles (AGV) for consideration. It’s understandable since both AMRs and AGVs are essentially motorized utility carts designed to move things. However, while AGVs have a purpose and place in manufacturing, they are not interchangeable with AMRs. There are key differences between the two that, if not understood, can — and often do — lead to disappointment.

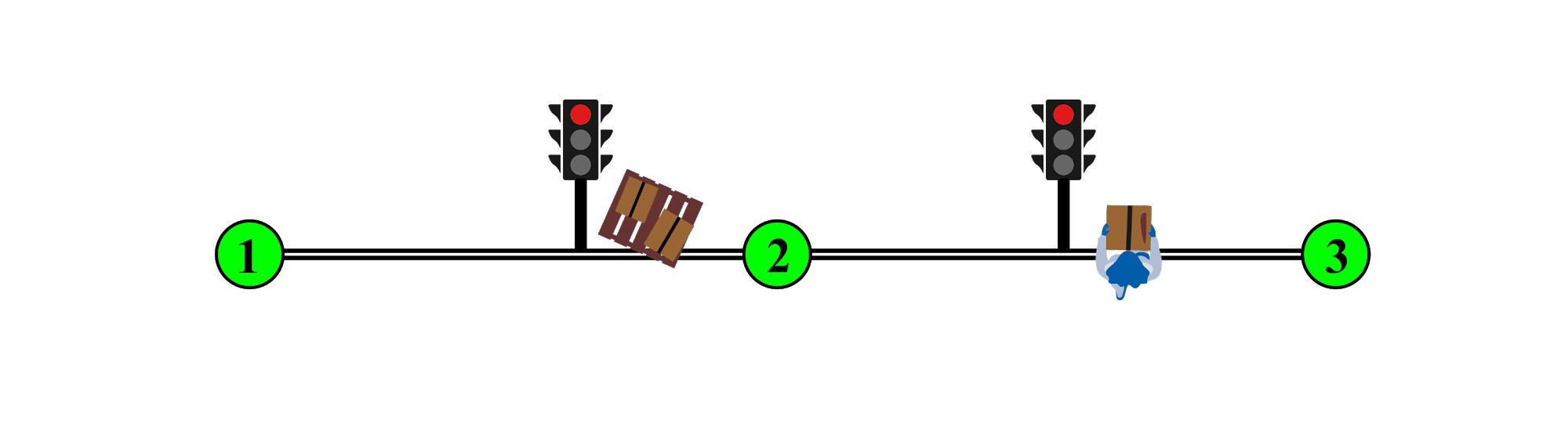

AGVs are often compared to a train and require a predefined path in the form of metallic tape or a physical track, which it cannot stray from. This means that if something is blocking that path, the robot has to wait till the path is cleared and it can continue unobstructed.

AGVs are the first wave of industrial robotics. Around since the 1950s, AGVs aren’t necessarily sophisticated, but they can be effective depending on need.

AGVs move along fixed routes, dependent on ground-embedded wire systems, magnets, or lasers for movement. They may contain rudimentary sensor systems that keep them from colliding with unanticipated obstacles, but an AGV likely would not be intelligent enough to avoid the obstacle altogether. That may not sound like a big deal, but it can be should you decide to rearrange the layout of a department or work station. AGVs cannot adapt to change without costly routing reconfiguration.

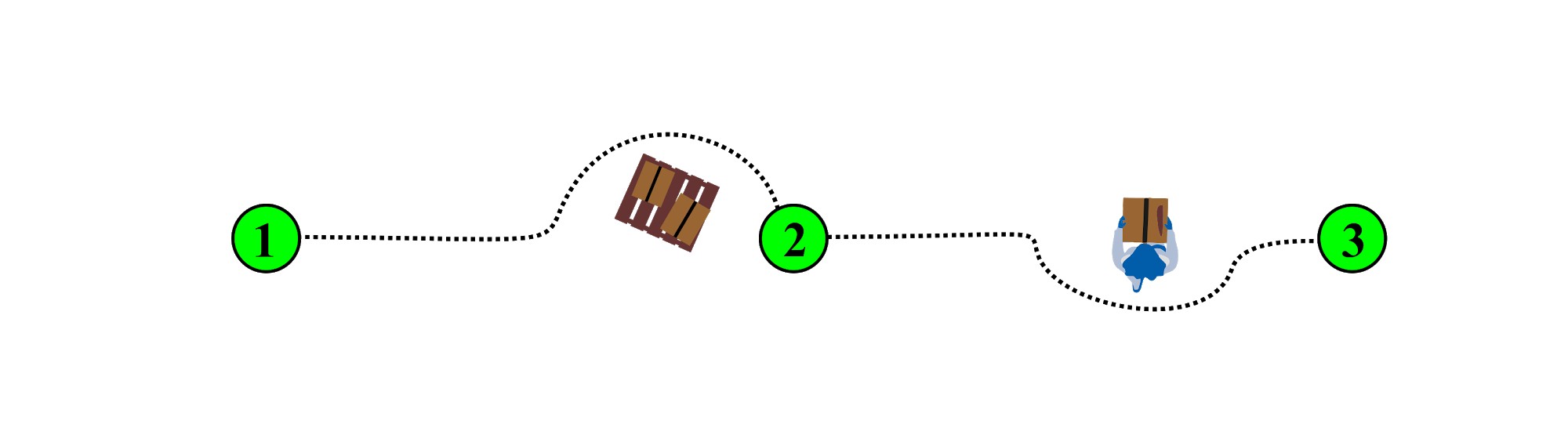

AMRs move independently. If their path is blocked, sensors and software combine to find — and take — an alternate route. Since AMRs aren’t restricted to predefined paths, they align with a large number of use cases.

AMRs are equipped with advanced computers and sensor systems, making them self-sufficient.

The onboard technology allows AMR industrial utility carts to be programmed to follow digital maps they create to navigate shop floors without aid of ancillary infrastructure. Likewise, AMRs are capable of processing, understanding, and responding to their environments in real-time. This independent “thinking” is a huge advantage over AGVs as it dramatically increases workplace safety.

AMRs can be impressively complex but not every situation requires it. That’s what led MūL Technologies to develop our Mobile Autonomous Robotic Cart (MARC). Our powerful, yet uncomplicated industrial cart prices out at about one-fifth of the over-designed competition and has many benefits:

In an AGV vs. AMR world, the differences in motorized utility carts can be subtle or substantial — but the advantage lies with AMR and innovations like MARC. Contact the MūL Technologies team to learn more about the right robotics for your operation. Isn’t it time you met MARC?